PURlogic® Fast 2-component frame foam

2C door-frame foam PURlogic Fast

DRFRMFM-2C-PURLOGIC-FAST-400ML

Art.-no. 0892144

EAN 4053479223766

Register now and access more than 125,000 products

Very quick to reach final strength

Reduces spread time to 60 minutes, saving time and money

Good adhesive properties

Good adhesion to virtually all surfaces found in construction

Dimensionally stable foam

No pressure needed once spreading time is reached

Tested product properties

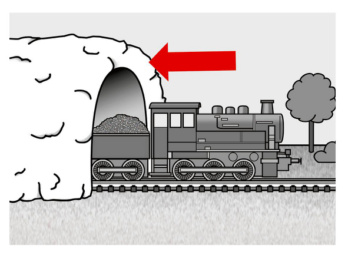

- Joint sound insulation. Reduces noise level at RST,w = 61 dB in accordance with DIN 52210

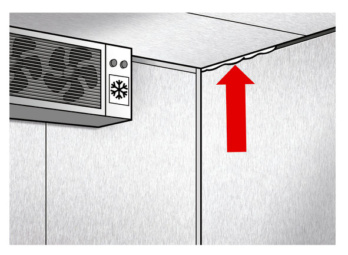

- Thermal conductivity. Reduces thermal loss at 0.035 W/(mK) in accordance with DIN 52612

- Air permeability. Prevents draughts, based on DIN 18055/EN 42

- Water vapour permeability. Tested in accordance with DIN EN ISO 12572

- Energy saving in accordance with the German Energy Conservation Ordinance (EnEV). Heating cost savings of 9 %, based on DIN 18055/EN 42

- General test certificate from construction authorities. Complies with building material class B2 in accordance with DIN 4102, Part 1

- EMICODE-certified

Fine-celled and uniform foam structure

Silicone- and solvent-free

Resistant to ageing

Our products featuring the EMICODE label are low-emission/low in harmful substances. The EMICODE classification system awards labels to construction products that comply with the very stringent health and environmental requirements of recognised institutes.

EMICODE EC1plus: Very low emissions: The EMICODE classification system distinguishes the environmental and health compatibility of construction products. The lowest-emission products bear the EC1plus mark.

Adheres to concrete, stone, hard PVC, metal and wood. Does not adhere to polyethylene, silicone, PTFE and grease. Primer must be applied to porous and absorbent surfaces. The despreading time can increase significantly with damp building surfaces. Moisture does not need to be added (wetting the adhesive surfaces) with 2-component foams.

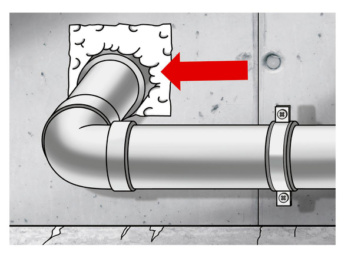

| Technical overview table for Purlogic® PU foams and spray cork | |||||||||||||||||

| Technical features | Main area of application | ||||||||||||||||

| Würth product Art. no. | Yield free-foaming up to … | Adhesive-free at +20°C from … min | Can be cut from … min | Can be spread from … min (curing) | Can be processed (substrate/environment) from … °C | Can be processed (can temperature) from … °C | UV-resistant | Building material class in accordance with DIN 4102 | Thermal sealing between window frame and wall | Sound insulation for window joints | Sound insulation in door frames | Fixing and filling of door frames | Filling, sealing and insulating cavities | Sealing and filling of connection joints for roof elements | Filling openings for piping | Setting of bath and shower trays | Bonding stairs |

| PURLOGIC® TOP 0892 142 0892 142 1 | 40 l | 7 | 40 | - | - 5 | +5 | No | B2 | ⎷ | ⎷ | O | O | ⎷ | ⎷ | ⎷ | O | O |

| PURLOGIC®Flex 0892 142 8 | 18 l | 6 | 20 | - | - 15 | 0 | No | B2 | ⎷ | ⎷ | O | O | ⎷ | ⎷ | ⎷ | O | O |

| PURLOGIC®EASY 0892 143 | 30 l | 7 | 12 | - | - 5 | +5 | No | B2 | ⎷ | ⎷ | O | O | ⎷ | ⎷ | ⎷ | O | O |

| PURLOGIC®FAST 0892 144 | 10 l | 7 | 15 | 60 | +10 | +10 | No | B2 | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | ⎷ | O |

| PURLOGIC® SPRINT 0892 146 | 4.3 l | 3 | 9 | 20 | +10 | +10 | No | B2 | O | O | ⎷ | ⎷ | O | O | O | O | ⎷ |

| PURLOGIC®Turbo 0892 147 | 5.5 l | 1,5 | +5 | 20 | +10 | +10 | No | B2 | O | O | ⎷ | ⎷ | O | O | O | O | O |

| Dispersion spray cork 0892 140 | 500 ml | x | x | - | +5 | +5 | Yes | B2 | ⎷ | ⎷ | O | O | ⎷ | ⎷ | O | O | O |

| PURLOGIC®Premium 0892 142 4 | 50 l | 7 | 40 | - | -5 | +5 | No | B1 | ⎷ | ⎷ | O | O | ⎷ | ⎷ | ⎷ | O | O |

| PURLOGIC®Easywhite 0892 143 300 | 25 l | 15 | 60 | - | +5 | +5 | No | B1 | ⎷ | ⎷ | O | O | ⎷ | ⎷ | ⎷ | O | O |

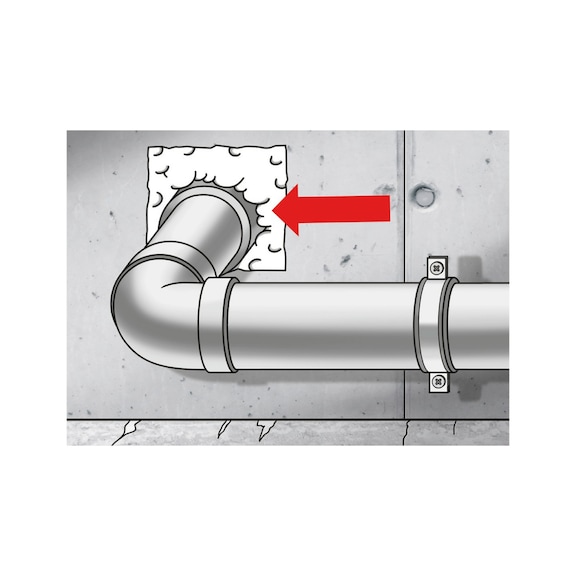

| O = not suitable ⎷ = suitable | |||||||||||||||||

EMICODE EC1plus: Very low emissions: The EMICODE classification system distinguishes the environmental and health compatibility of construction products. The lowest-emission products bear the EC1plus mark.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

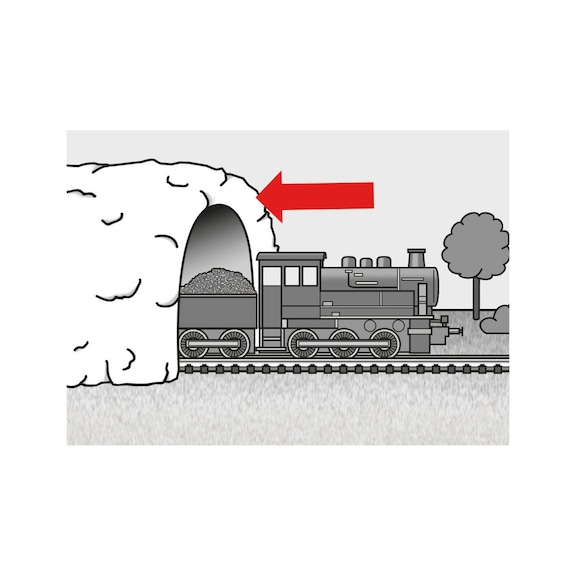

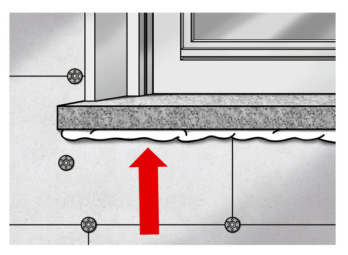

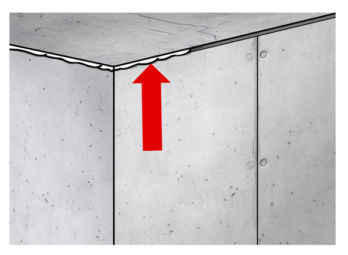

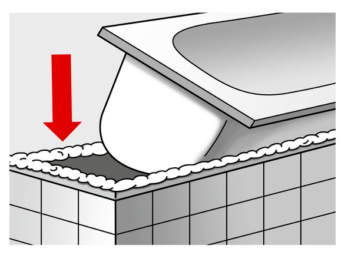

For high-quality and secure wooden and steel door frame installation, window sill connections*, for filling larger cavities, such as roof beams, bath and shower tub filling and model and mould construction.

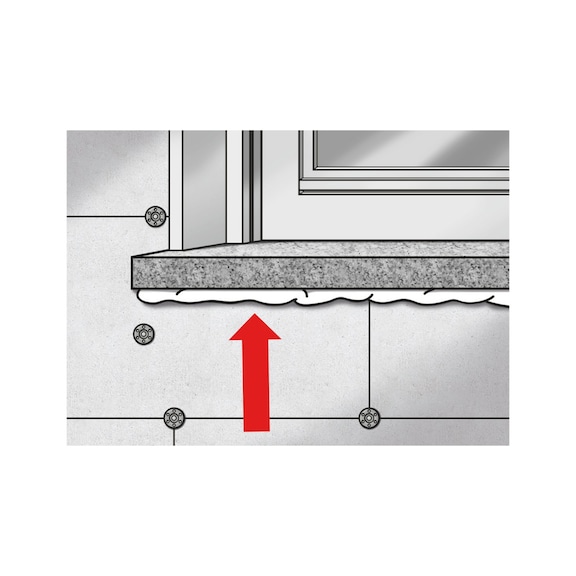

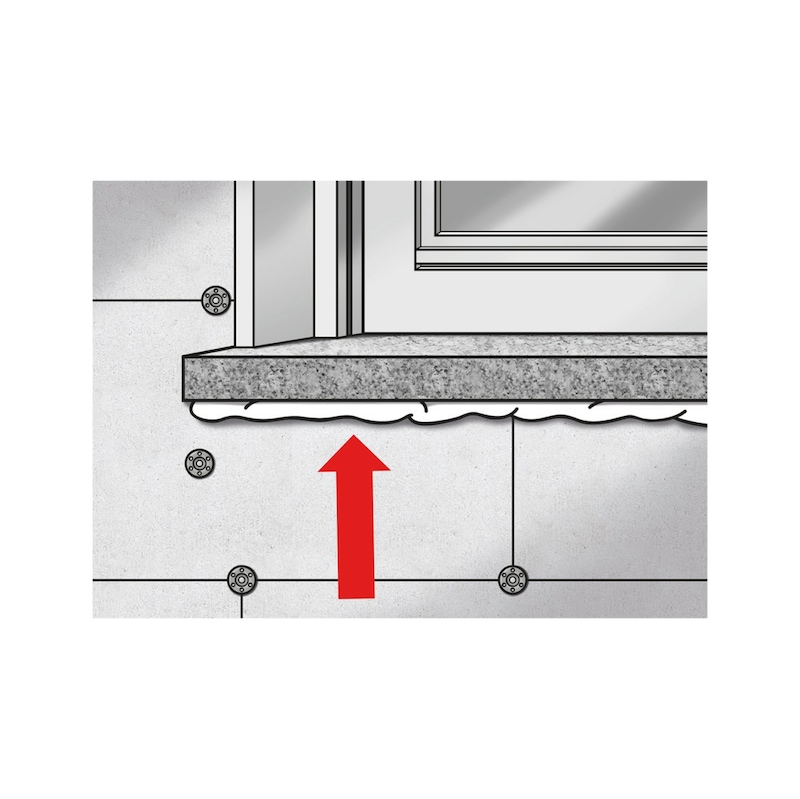

* Must be protected from a compressive load with a sufficient supporting load.

Adheres to concrete, stone, hard PVC and wood.

Cover the surfaces adjacent to the working area before starting work. Screw the enclosed adapter tube onto the valve. Turn the inner part of the red rotary disc 5 times to the right. This opens the B component. Shake the can vigorously, with the valve facing downwards, approx. 20 times so that the can contents are mixed and the foam quality is optimised. The foam needs to be a uniform shade of lime green. If this is not the case, shake the can again.

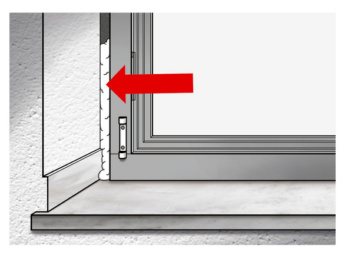

Wooden door and window frames:

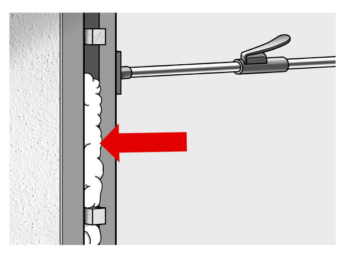

For installing door and window frames, the structural components must be aligned and fastened in accordance with the latest standards. Use spreaders for door frames. Then apply the foam at three points on the left and right-hand sides. Only fill the joints or cavities to 50% with foam because the foam will expand.

Steel door frames:

Steel door frames must be fully bonded with foam and must also be secured mechanically. Cut away excess, fully hardened foam with a knife. Immediately remove splashes of foam with PURLOGIC Clean, Art. no. 0892 160.

For more information, please refer to the technical data sheet.

Chemical basis | Polyurethane prepolymer |

Colour | Green |

Smell/fragrance | Characteristic |

Moulded density | 46 kg/m³ |

Conditions for moulded density | in released form, tested in accordance with Würth test methods |

Cell structure | Fine |

Cell structure conditions | tested in accordance with Würth test methods |

Working life | 4 min |

Tack-free after | 9 min |

Conditions for being tack-free | at 23°C and 50% humidity |

Can be cut after | 15 min |

Conditions for ability to cut | at 23°C and 50% relative humidity |

Full resilience | 1 h |

Conditions for full resilience | at room temperature |

Final spreading possible after | 60 min |

Conditions for final spreading | at room temperature |

Min./max. processing temperature | 10 to 25 °C |

Min./max. ambient processing temperature | 10 to 25 °C |

Min./max. surface processing temperature | 10 to 25 °C |

Min./max. processing temperature for can | 10 to 25 °C |

Min./max. temperature resistance | -40 to +90 °C |

Max. short-term temperature resistance | 120 °C |

Compression strength | 5 N/cm² |

Compression strength conditions | based on DIN 53421, at 10% compression |

Min. combined tension and shear resistance | 9 N/cm² |

Conditions for combined tension and shear resistance | in accordance with DIN 53427 |

Elongation at break | 30 % |

Yield (volume) approx. | 11 l |

Conditions for yield | Tested in accordance with Würth test methods |

Contents | 400 ml |

Building material class | E - Normally inflammable |

Building material class conditions | in accordance with DIN EN 13501-1 |

Resistance against | Aging |

Shelf life from production | 12 Month |

Conditions to maintain shelf life from production | upright and dry storage area |

Sustainability | Pollutants / Emissions |

ANGLADAPT-FMGUN-RDPIP

Just leave the field empty if you don't know the packaging unit when directly entering the article number in the shopping basket or when importing with v

VVVV = 4 digits for prefix number (please note that the first digit is currently always 0)

AAA = 3 digits for dimension part 1

BBB = 3 digits for dimension part 2

Example article number structures:

Example 1: Screw with dimensions of 4x10 mm:

VVVVAAABBB

00574 10 (2 spaces between the 4 and the 10)

Example 2: Screw with dimensions of 10x20 mm:

VVVVAAABBB

005710 20 (1 space between the 10 and the 20)

Example 3: Flat washer with an internal diameter of 6 mm:

VVVVAAABBB

04076

The displayed price is always in line with the displayed packaging, if the PU is 250 the price for 250 units, if the PU is 300 the price for 300 units.

Price with price key representation (PSL):

The price always applies to a quantity ruled through the price key:

Price for 1 unit

Price for 100 units

Price for 1000 units

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!