FSK system adhesive

System adhesive, FSK

ADH-PVC-FSK-CLEAR-TUBE-200G

Art.-no. 089210009

EAN 4046777772289

Register now and access more than 125,000 products

User-friendly

Thixotropic setting prevents dripping on vertical bonds.

Suitable for indoor and outdoor use

- Guarantees weatherproof bonding

- Effective resistance to UV and weathering

Short curing time

Rapidly ready for further work.

Excellent resistance to media

- Resistant to water, oil, petrol and alcohol

- Short-term resistance to diluted acids and alkaline solutions

Silicone-free

- When bonding additional profiles to decorative wood surfaces, it must be ensured that the additional profiles lie flat on the window profile and no adhesive leaks onto areas not being glued. The additional profiles glued in this way must not be exposed to increased temperature loads/solar radiation (≥ +25°C) for a period of 1 week. Failure to observe these conditions may result in the formation of bubbles in the acrylic layer.

- Not to be used with pressure pipes.

- Adhesive may only be processed with the appropriate type 10 and type 20 cleaners.

- The FSK system adhesive can only bridge adhesive gaps ≤ 0.1 mm by a friction-locking connection.

- The applied adhesive quantity is to be selected depending on the material thickness; the adhesive may “bleed through” or lead to the formation of predetermined breaking points.

- Adhesive joint can take weight after 16 hours, depending on situation, complete hardness may take up to 8 weeks to achieve.

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

For cold-welding hard PVC in plastic window construction and sanitary applications, for bonding all additional hard PVC profiles, angular fillets and cover strips, etc. Cold welding of PVC pipes (excluding high-pressure). Trade fair stand and sign construction:: Structural adhesion of integral rigid foam panels made of hard PVC.

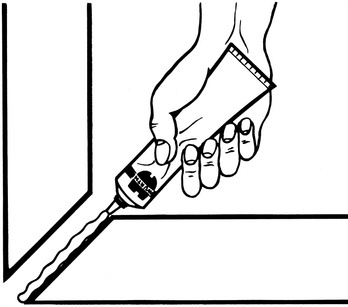

Clean the PVC adhesive surfaces of dirt and grease with cleaner type 10. Apply the adhesive on one side and join the parts immediately (within 30-60 sec). Hold/press the parts until functional strength is achieved. When bonding additional profiles to film-laminated surfaces, make sure that these lie flat on the window profile and that no glue escapes.

For more information, please refer to the technical data sheet.

Weight of content | 200 g |

Chemical basis | Vinyl chloride polymer |

Colour | Transparent |

Smell/fragrance | Characteristic |

Density/conditions | 0.99 g/cm³ / at 20°C, 50% relative humidity |

Viscosity | 4000 mPas |

Viscosity conditions | at 23°C |

Curing time/conditions | 24 h/ at 20°C |

Min./max. processing temperature | 5 to 35 °C |

Min./max. temperature resistance | -40 to +130 °C |

Min. flashing point | -14 °C |

Min./max. functional strength | 2-4 min |

Max. functional strength | 4 min |

Min. initial strength | 4 min |

Application quantity per running metre/conditions | 8 g/m / for 20-mm wide bar |

Max. application quantity in surface bonding | 400 g/m² |

Shelf life from production/conditions | 24 Month / at 15°C to 25°C |

Ultraviolet resistance | Yes |

Solvent-free | No |

Silicone-free | Yes |

Resistance against | Alcohol, Petrol, Oil, Water |

Contents | 204.08 ml |

Short-term resistance against | Diluted acids, Diluted lye |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!