Polishing Ring Hard

Polishing ring hard

POLRG-HARD-(F.EPM200-E)-D150MM

Register now and access more than 125,000 products

- Up to three times higher material removal power with shorter processing times

- Lower coating weight for easier handling

- Less contact pressure necessary, resulting in less fatigue

- Cost savings due to markedly lower paste consumption compared with conventional cloth discs

- Streak-free working due to the continuously changing surface structure and the piled folding

- The polishing rings are made of a purely mechanically bonded, innovative and flexible matted fleece specially developed for high-gloss polishing

- 10-ply

Apply the paste with the machine running!

Datasheets(X)

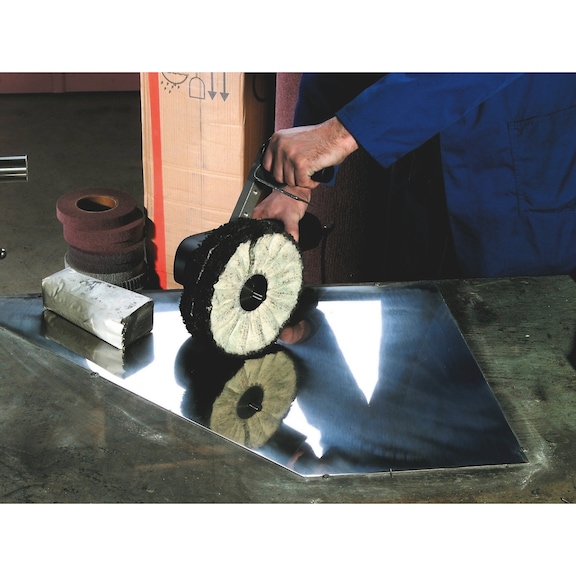

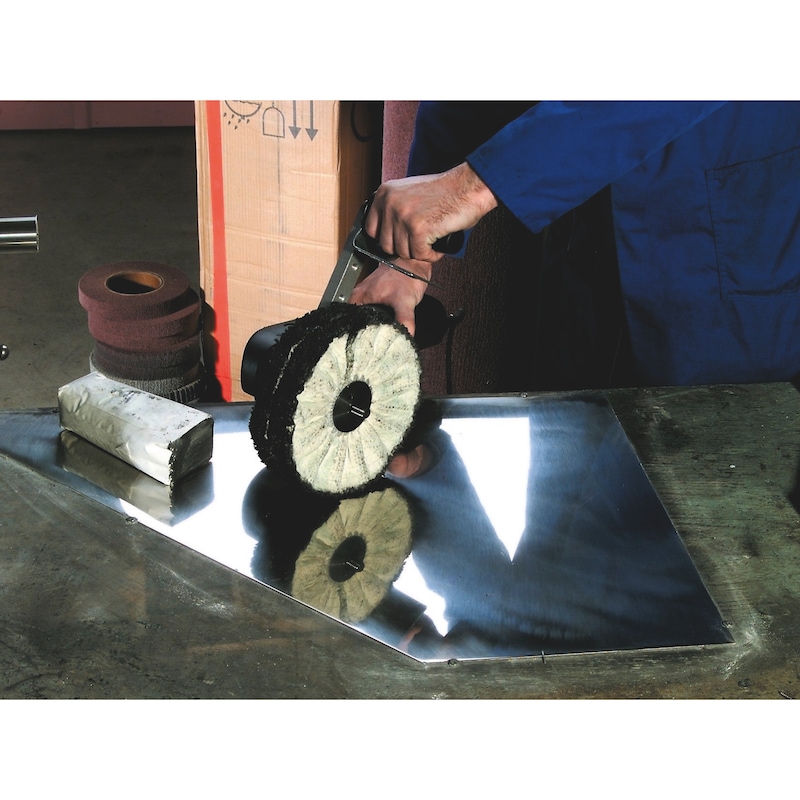

Pre-polishing of non-ferrous metals, particularly soft light metal alloys, polishing of steel and stainless steel in conjunction with appropriate polishing paste or buffing paste.

Materials to be processed: Steel, stainless steel and non-ferrous metals

The better the pre-sanding, the simpler and shorter the effort required for polishing. Metals should be pre-sanded with 280 or 320 grain abrasive cloth.

Every work step should be crosswise or diagonal to the previous one.

Important: If the individual work steps are not carried out carefully, flaws in the surface become even more obvious during buffing.

A separate set of polishing rings should be used for each paste. This prevents mixing of different pastes and impairment of the result.

Clean clogged polishing rings by gently pressing with a wire brush.

Remove polishing residues on the surface with brake cleaner.

The application recommendations have a general character depending on how good the initial surface is or how high the requirements for the final surface are.

Recommended working speed: approximately 25 m/s. (corresponds to stages 4–6 for PM 200-E).

The correct procedure and speed must be determined on a case-by-case basis.

Perform preliminary testing or conduct your own tests!

Diameter (Ø) | 150 mm |

Suitable for stainless steel | Yes |

Suitable for steel | Yes |

Suitable for non-ferrous metals | Yes |