Adhesive lubricant HHS 2000®

Adhesive lubricant, HHS 2000

ADHLUB-HHS2000-500ML

HHS

HHS2000

Register now and access more than 125,000 products

- Eliminates squeaks and creaks and has excellent flow and penetration performance, as well as good corrosion protection.

- Highly adhesive lubricant that is not spun away when used on turning and rotating parts

- Compatible with O-rings/X-rings and plastics. Neutral behaviour on painted substrates.

- Resistant to splash water and salt water, weak acids and bases

- Free from silicone, resin and acids

The usage instructions are recommendations based on the tests we have conducted and our experience; carry out your own tests before each application. Due to the large number of applications and storage and processing conditions, we do not assume any liability for a specific application result. Insofar as our free customer service provides technical information or acts as an advisory service, no responsibility is assumed by this service except where the advice or information given falls within the scope of our specified, contractually agreed service or the advisor was acting deliberately. We guarantee consistent quality of our products. We reserve the right to make technical changes and further develop products.

Datasheets(X)

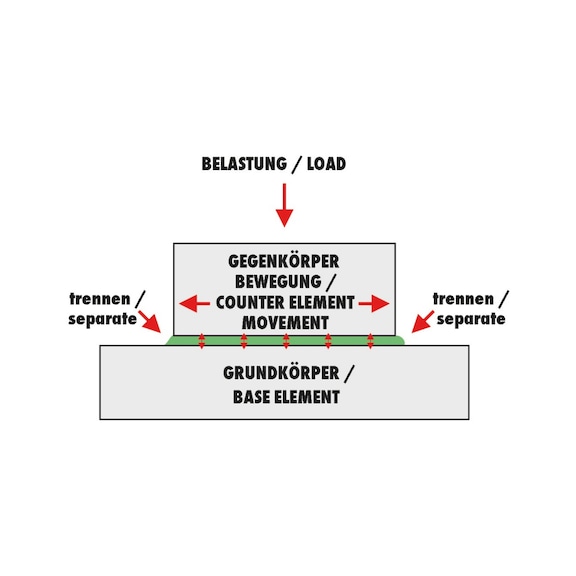

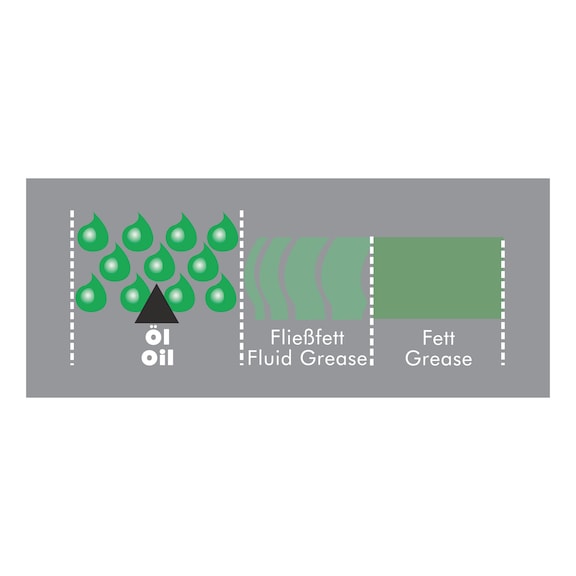

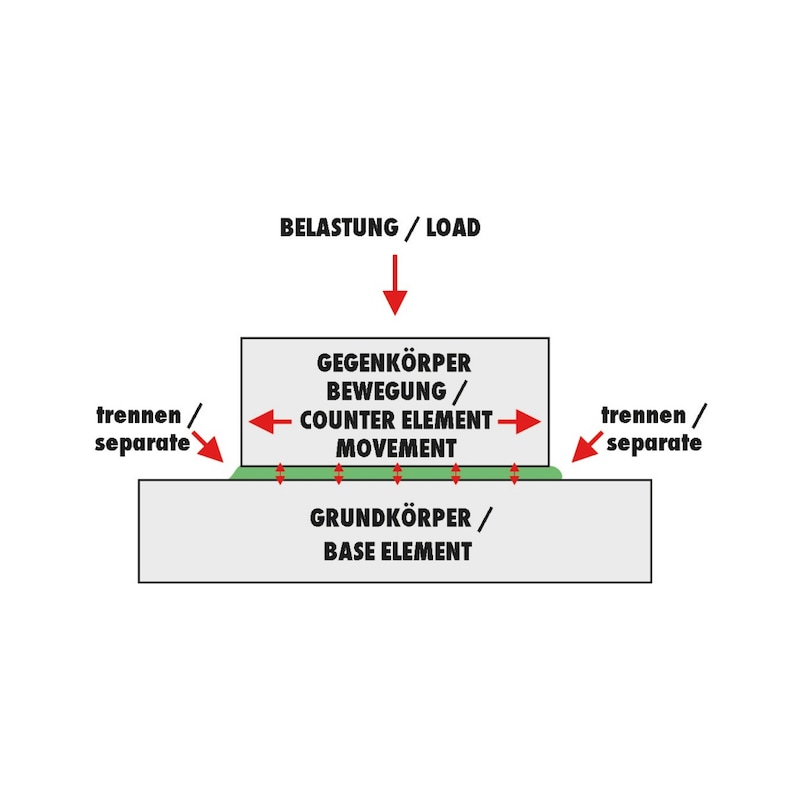

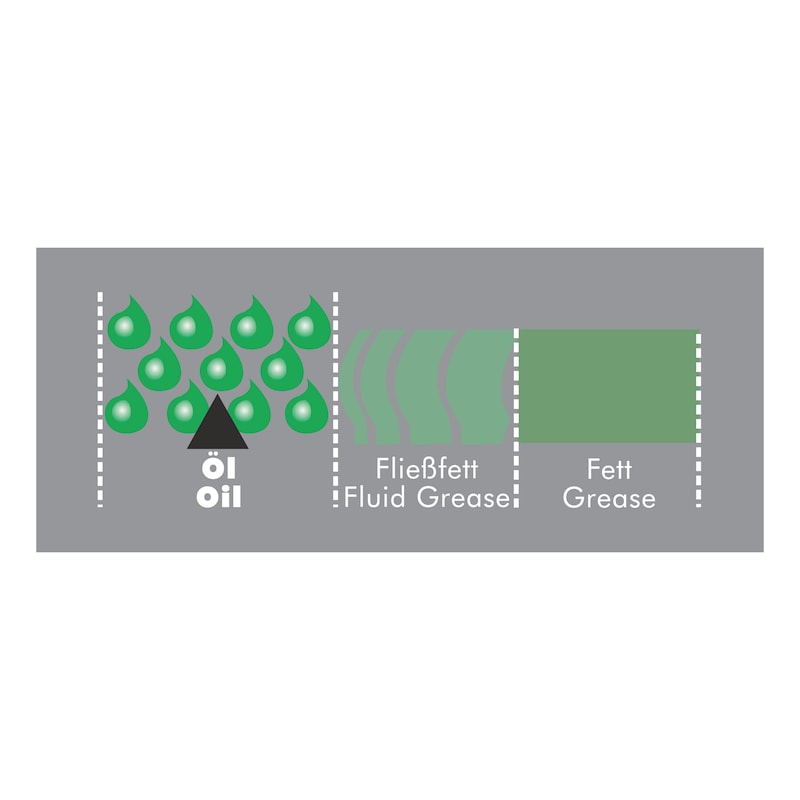

Extremely high-pressure-resistant partly synthetic oil for universal lubrication and for high pressure loads.

Suitable for universal lubrication and for high pressure loads, e.g. shifting, accelerator and clutch linkages, Bowden cables, pins, joints, hinges, reversing levers, lock strikers, drag link ends, slide rails, chain wheels, toothed racks, open gearwheels and much more.

Carefully and thoroughly pre-clean the lubrication points before each application. Shake the can before use, spray the parts and let it take effect briefly.

After use, spray the spray head upside down until empty.

Chemical basis | Hydrocarbon |

Oil basis | Mineral oil |

Colour | Yellowish |

Smell/fragrance | Oil |

Density | 0.742 g/cm³ |

Density conditions | at 20°C |

Min. temperature conditions | -25 °C |

Max. temperature conditions | 180 °C |

Max. temperature resistance | 200 °C |

Min. flashing point of active ingredient | 300 °C |

Kinematic oil basis viscosity | 1500 cSt |

Silicone-free | Yes |

Acid-free | Yes |

Resin-free | Yes |

AOX-free | Yes |

Resistance against | Salt water |

Contents | 500 ml |

Container | Can |

Shelf life from production | 24 Month |

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!